Stainless Steel

Wide Coil

Stainless Band’s new in-house slitting line offers the capability for slitting up to 1250mm wide coil x 0.20 - 1.50mm thickness in 304/316L/321 and 430/409. Other grades are available on request. Also offering material as PE or PVC coated/with foil. Coil sizes range from 200kgs to 3500kgs depending on final widths.

This unique line means Stainless Band can handle coils up to 8 tonnes on-site and process in Bingley. This will reduce pricing and also improve delivery times to clients for wide coil and also standard products that Stainless Band provide.

I would like to know more about

Wide Coil Properties

Wide Coil Characteristics

Wide Coil Safety and Finishing

Physhical Properties

Density 8.03 kg/cm3 - 0.29 ilbs/in3

Modus of elasticity 200 Gpa

Electrical resistivity 0.730mm2/m

Thermal Conductivity BTU/hr/ft2/ft/°F (W/ M•K)

at 212 °F (100 °C) - 9.4 (16.2)

at 932 °F (500 °C) - 12.4 (21.4)

Mean Coefficient of Thermal Expansion, in/in/oF (um/M*K)

32-212 °F (0-100°C) - 9.4 x 10-6 (16.9)

32-600 °F (0-315°C) - 9.6 x 10-6 (17.3)

32-1000 °F (0-538°C) - 10.2x 10-6 (18.4)

32-1200 °F (0-649°C) - 10.4 x 10-6 (18.7)

Melting Range, °F (°C) - 2550 - 2650 (1399 - 1454)

Mechanical Properties - Values at 68°F 20°C

Type

| ASTM304304 L316316 L | EN1.43011.43061.44011.4404 | Tesnile (Mpa)Min515515515485 | YieldMin205205205170 | ElongationMin %40404040 | Hard MaxBrinell217217 |

Weights and Packaging

Coil weights from 1000 - 2000 kgs, other weights upon request. Can also be supplied in sheet from, 2000 x 1000mm - other sizes on request.

Export packed in weather proof packing suitable for container shipping. Fumigation of wooden packing materials can be arranged if required.

Chemical Composition (typical)

Type

| ASTM304304 L316316 L | EN1.43011.43061.44011.4404 | C0.070.030.080.03 | Cr17.5 - 19.517.5 - 19.516.0 - 18.016.0 - 18.0 | Ni8.0 - 0.58.0 - 12.010.0 - 14.010.0 - 14.0 | Mo2.00 - 3.002.00 - 3.00 |

Wide Coil Characteristics

Made from stainless steel AISI 304/316.

They offer good formability, corrosion resistance, toughness and good mechanical properties. As a result they are widely used for insulation and engineering applications. These grades are non-magnetic in the annealed condition.

Finish

2B (matt) finish supplied as low reflective finish.

Patterned or polished finish material with or without PE coating can be supplied on request.

Safety

There are no known health risks in handling stainless steel although it is recommended that gloves should be worn in case of sharp edges.

Good lifting practice techniques should always be followed when handling these products.

Stainless Steel Wide Coil products that work in the real world

Processed from our in-house facility in Bingley West Yorkshire, UK.

-

Petrochemical industry

-

Automotive industry

-

Construction industry

-

Insulation industry

Download our

Wide Coil datasheet

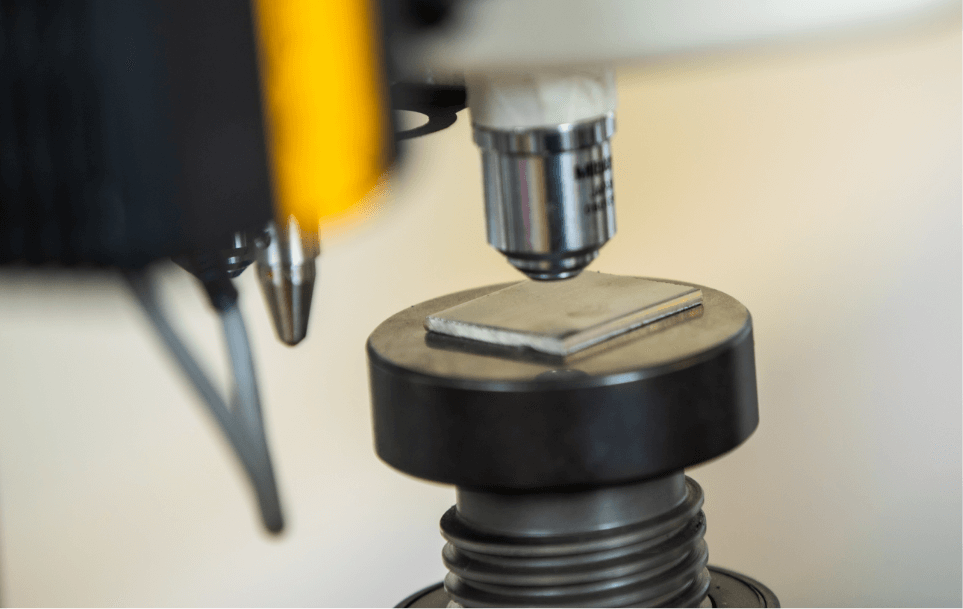

Quality testing is performed throughout processing to give our customers complete peace of mind