-

Petrochemical industry

-

Automotive industry

-

Construction industry

-

Insulation industry

Edge Conditions and

Stainless Steel Strip

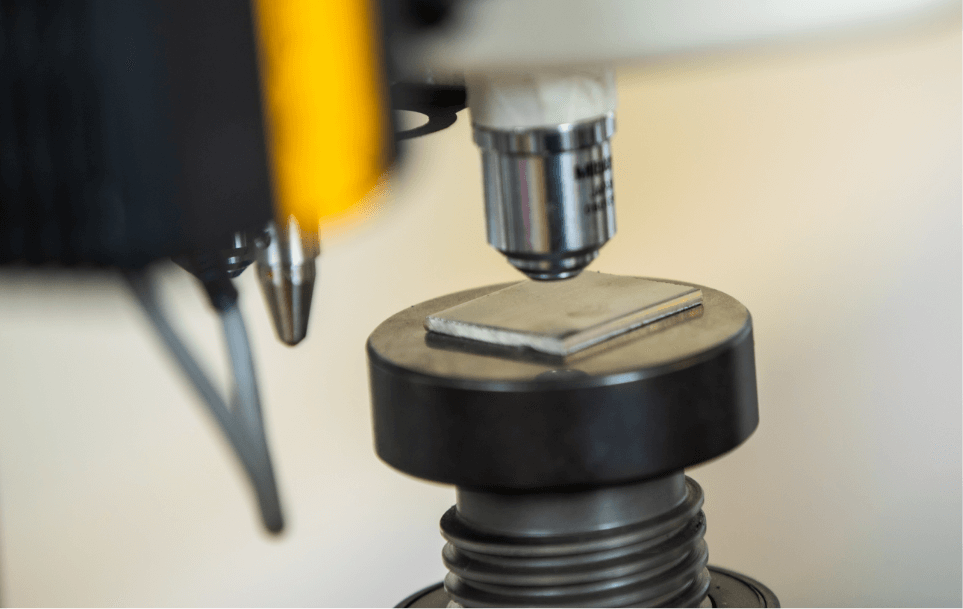

Health and safety is of paramount importance to all industries. Our introduction of edge rounding and dressing eliminates the sharp edge, known as a burr that occurs during the production of steel strip and coil.

Our updated edge dressing machines are capable of producing both large and small quantities of stainless steel strip and coil with a kinder safer rounded edge or full round edge.

We can edge dress on site to a maximum width of 150mm.

Certificates of conformity, showing the exact chemical and mechanical composition of the material are supplied with each delivery.

Edge Finishes

GK - Slit edge

Standard material with a maximum burr 5% of the material thickness.

WAK - Flat rolled edge

Many clients require material to have a deburred edge (WAK) .

This can improve product performance but also reduce the risk of Health And Safety issues when handling sharp materials.

The safe alternative to dangerous sharp edges

Used in a wide range of end uses

Download our

Edge Conditions datasheet

Quality testing is performed throughout processing to give our customers complete peace of mind